Hydrocracker

The objective of hydrocracking is to convert heavy oil feedstocks into high quality, lighter fuel products such as gasoline, naphtha, jet or kerosene, diesel, and hydrowax (unconverted bottoms) which can be used as petrochemical plant feedstock or lube basestock. A two-step process is typically employed. In the first (pretreat) step, polyaromatic compounds are saturated and organic nitrogen and sulfur are converted to ammonia and hydrogen sulfide. The organic nitrogen contained in the feedstock would otherwise inhibit the activity of the cracking catalyst. In the second (cracking) step, higher molecular weight hydrocarbon molecules are preferentially cracked over an acidic metal-containing hydrocracking catalyst. The product yields and product properties are determined by the feedstock, the cracking catalyst selectivity and the process conditions.

Figures

(source: http://www.flexim.com/us/flexim-oil-gas/refinery/field-proven-worldwide/fluidized-catalytic-cracker)

(source: http://www.biodis-swiss.com/hidrocrackingen.htm/http://www.ec.all.biz/hydrocracking-hydrotreating-reactors-g10091)

Videos

References

http://www-static.shell.com/static/criterion/downloads/pdf/cr_z_hc_pd.pdf

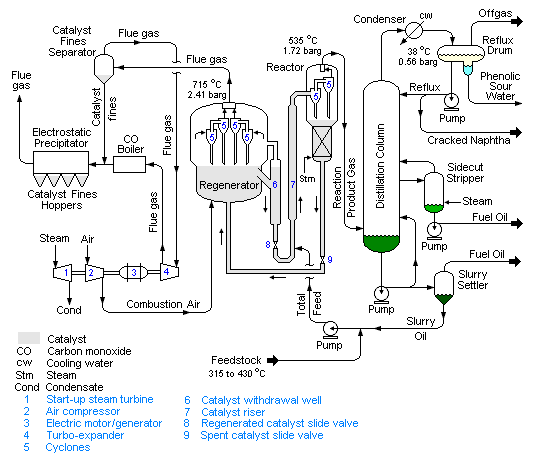

http://en.wikipedia.org/wiki/File:FCC.png

http://www.aral.de/aral/sectiongenericarticle.do?categoryId=4000017&contentId=56242

http://www.exterran.com/Products/critical-process-equipment/hydrocracking-hydrotreating-reactors