Hopper Feeder

Hopper Feeders provide the most efficient and economical method of conveying bulk materials such as biomass, with the ease of controlling feed rate. Feeders satisfy a range of applications from light-duty food and chemical to heavy-duty quarry applications in a cost effective way. For each application a feeder is sized and equipped with various tooling and options to suit. Most feeders consist of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gears are jogged. Through drive of the motor, the two eccentric shafts start rotating to produce a linear huge power which forces the feeder to vibrate. Through the vibration, the biomass materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller parts will fall down, and avoiding the further crushing, so screening purpose can be reached.

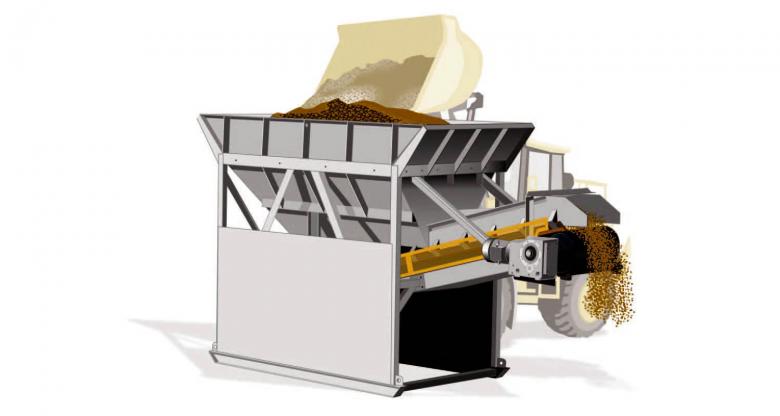

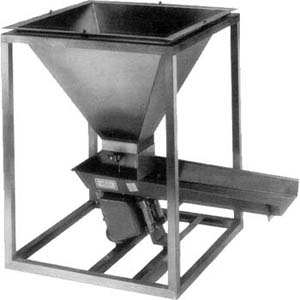

Figures

(Source: http://www.rocksystems.com/machinery/hoppers-and-feeders/front-end-loader-hoppers/101-36.html)

(Source: http://www.best-vibrating-feeders.com/)

Video

References

1. General Kinematics Corporation. "Vibrating Feeders for Stockpile and Reclaim." Vibrating Feeders for Stockpile and Reclaim | GK Feeders. General Kinematics Corporation, n.d. Web. 12 Dec. 2012. http://www.vibratingfeeders.com/reclaimarticle.cfm.

2. "Electromagnetic Vibrating Feeders-1,250 Lbs/hour-7.5 Tons/hour." Electromagnetic Vibrating Feeders-1,250 Lbs/hour-7.5 Tons/hour. N.p., n.d. Web. 12 Dec. 2012. http://best-vibrating-feeders.com/electromagnetic-vibrating-feeders.htm