Gasification of Wood Pellets

Wood pellets are non-ideal downdraft gasifier fuel. However, their ubiquity and relatively consistency make them an obvious contender for a gasifier fuel standard. They are the closest thing we have in contemporary times to the standardized chunkette production and delivery infrastructure that supported the Imbert in WWII. The main positive feature of wood pellets is they are consistent dry chunky pieces of wood. They're also nice and smooth, so their mechanical flow characteristics are good. Most of the bridging problems others are reporting on wood chips go away on wood pellets.

The main problems with wood pellets in a gasifier are: They fall apart when exposed to moisture and make a giant sawdust mess, which plugs the reactor. They are very dense and small, thus have a higher "fuel to open space" ratio than desired. They create a heavy bed that is much more difficult to penetrate with air, thus combustion and tar cracking is challenged. They appear to pyrolyize slower than natural biomass chunks. This seems to follow both from their high density as well as the lack of the usual grain pathways for gas flow.

In one not atypical gasification system fuel, initially wood pellets, is supplied from an indoor wood pellet storage site into the gasification plant. The fuel is fed through lock hopper systems by feeding screws into the lower section of the gasifier’s fluidized bed. Producer gas is created in the gasifier and this is a fuel gas and chemcial source which can be used to replace fossil fuels in a wide range of devices, including road and rail transport.

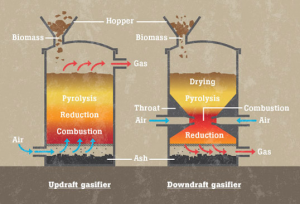

Gasification of wood and wood-type residues and waste in fixed bed or fluidised bed gasifiers with subsequent burning of the gas for heat production is state of the art in Northern Europe. However, the market has hardly yet been exploited even in those countries where the wood gasifiers which are employed in the Scandinavian countries are used almost almost entirely just for heat generation. Biomass is a sustainable energy resource which is destined to play an important role in future energy production and as an organic chemical raw material supply source, with biomass gasification the most promising conversion technology and very effective in reducing greenhouse gas emissions. Biomass is converted into a gaseous mixture of hydrogen, carbon monoxide, carbon dioxide, and other compounds by applying heat under pressure in the presence of steam and a controlled amount of oxygen (in a unit called a gasifier). The biomass is broken apart chemically by the gasifier’s heat, steam, and oxygen, setting into motion chemical reactions that produce a synthesis gas, or “syngas”-a mixture of primarily hydrogen, carbon monoxide, and carbon dioxide. It is this synthesis gas which can then be further reacted and refined to replace oil as a raw material for use in refineries.

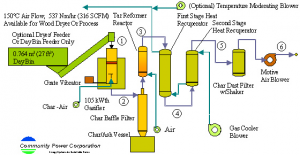

Flow Diagram

(Source: http://www.ashden.org/images/technologies/Gasifier_2_0.jpg)

(Source: http://www.abe.msstate.edu/Biomass/images/flow_diagram_gasifier_jpg_files/flow_diagram_gasifier.jpg)

Equipment

Grate vibrator

Tar reformer reactor

Char baffle filter

Char dust filter with shaker

Char/Ash vessel

Temperature moderating blower

Gas cooling blower

Heat recuperator

Video links

Evergreen Fuel Gasification 1 - wood pellets powers truck - about

Gasifier Test with Wood Pellets