Gasification of Manure

In order to solve the challenge of high quantities of agricultural manure and of phosphorus balance in the environment without a necessity to restrict animal production, animal manure must be utilized on site or transported to places with a deficit of phosphorus. Since the transportation of raw slurry with its high water content is expensive and inefficient, farm‐scale mechanical separation of the manure (raw or anaerobically digested) into solid and liquid fractions may offer a solution . The liquid fraction can be used as nitrogen fertilizer, where as the phosphorus‐rich solid fraction could be further dried and thermally gasified to recover heat and electricity. When gasifying manure, the pre‐treatment involves solid‐liquid separation (mechanical separation, dewatering), drying and pelletizing. The national legislation should be considered when organizing the pre‐treatment. For example in Denmark, drying and pelletizing of manure is not allowed at farm‐scale due to the vicinity of pig feed. Slurry separation using screw presses, vibration filters or decanters is already practiced e.g. in Denmark and in the Netherlands using mobile, containerized units, easy to relocate from farm to farm (examples of Danish producers: Samson Bimatech, ManuPower, SB Engineering, Vredo; in the Netherlands more high‐tech including reverse osmosis and ultra filtration). In Denmark, the separation results in around one million tons of slurry separated each year (3% of total slurry production). Pelletizing of manure/digestate is still a novel technology, therefore not common on a commercial scale yet.

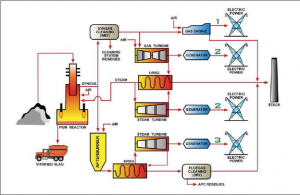

Flow Diagrams

(Source: http://www.ews-sa.com/gasification-process-chart.php)

Equipment

Videos

Gasiication Manure - Biogas

References

- http://balticmanure.odeum.com/download/Reports/Total/balticmanure_thermal_gasification_finalfinal_total.pdf

- http://www.green-energy-ukraine.com/images/gasification%20chart%20compressed.jpg