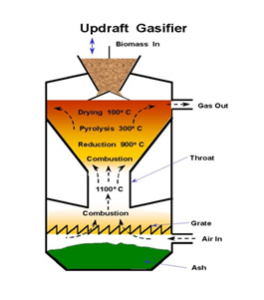

Updraft Gasification

Updraft (also counter-current) fixed bed gasification is a thermochemical conversion process that produces a synthesis gas, or “syngas”; this product gas can consist of a substantial amount of useful energy depending on the higher heating value of the fuel being used. This fuel, such as biomass material, will be applied to the top of the gasifier, and the gasifying agent, such as air, will be injected near the bottom of the reactor; the air will flow counter-currently to the fuel. This fuel will go through the different levels of temperature in the reactor, and the product gas will flow from the reactor without really interacting with the rest of the biomass/char regions.

One of the differences between updraft gasifiers and downdraft is that it doesn’t take as long for the start-up procedure for the downdraft gasifier setup; this is the process that many reactors must go through before going into daily operations, where the best temperatures/conditions for gasification are reached. The gas leaving the updraft gasifier will also have high tar content versus the product gas from a downdraft gasifier. Some of the advantages of the updraft gasifier are that it has a small pressure drop vs. the downdraft gasifier, and that is has a smaller tendency for ash fusion within the mass of converting material, which usually results in process problems.

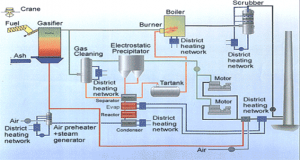

Flow Diagrams

(Source: http://www.jfe-eng.co.jp/en/news/2003/20031210.html)

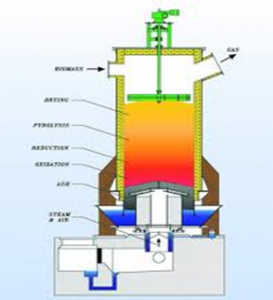

(Source: http://www.chamco.net/Gasification.htm)

(Source: http://www.indiamart.com/nilkanthengineers/gasifiers.html#updraught-gasifier)

Equipment

Boiler/Burner

Crane

Scrubber

Condenser

Electrostatic Precipitator

Gas Cleaning

Videos

Updraft Gasifier Reactor Process

Updraft Gasifier Reactor Layout

References

- http://www.nariphaltan.org/gasbook.pdf

- http://www.gasifyer.com/updraft_gasifier.htm

- http://www.greenstone.org/greenstone3/nzdl?a=d&c=hdl&d=HASH8ed9f6ceae3ba14a81f76a.8.2&sib=1&ec=1&p.a=b&p.sa=&p.s=ClassifierBrowse&p.c=hdl)

- http://en.wikipedia.org/wiki/Gasification#Counter-current_fixed_bed_.28.22up_draft.22.29_gasifier.

- http://www.youtube.com/watch?v=Kb1gofE26hM

- http://www.youtube.com/watch?v=sz0Ivlmb7U8