Fluidized Bed Gasification

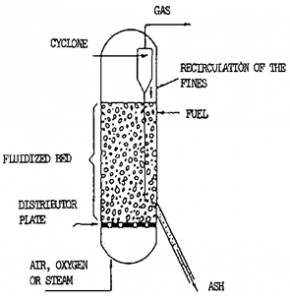

Fluidized bed gasification differs from updraft/downdraft methods of gasification; the gasifying agent (i.e. air) flows through the fuel of the process, which can be biomass, coal, and many other feeds; moisture content is more of an important factor in this process. A reactive material, such as sand, is also inside of the reactor; these particles will help to make the product gas from this gasifier react even further. As the gasifying agent passes through the fuel, it will keep this fuel suspended in midair; this suspension is the reasoning behind the name “fluidized bed gasification”. A second stream of a gasifying agent (that is not used to keep the fuel suspended) is usually needed for this process to be optimally efficient; a cyclone attachment can be used to separate the reactive particles, or char, from the syngas. This attachment may also increase the efficiency of this process.

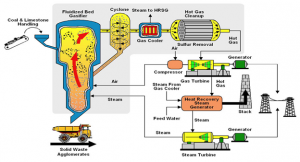

Flow Diagrams

(Source: http://energiterbarukan2.blogspot.com/)

(Source: http://www.fao.org/docrep/t0512e/T0512e0a.htm)

(Source: https://lh3.googleusercontent.com/kb88YDq0UcU-GPUb6hSbUiUIl_LQj6n3DnE1qN97ru7vvBn5KxoiFpGXVnjZ2S_YxCbeEw=s85)

Equipment

Cyclone

Hot Gas Cleanup

Generator

Heat Recovery System Generator

Compressor

Turbine

Distributor

Videos

CFD Simulation in CPFD Barracuda of a Fluidized Bed Gasifier

Fluidised bed technology: Generating options for tomorrow

References

- http://www.eai.in/ref/ae/bio/bgt/type/fixed_bed_gasifier.html

- http://www.bioenergy-noe.com/?_id=236

- http://www.netl.doe.gov/technologies/coalpower/cctc/cctdp/project_briefs/pinon/pinondemo.html

- http://www.fao.org/docrep/t0512e/T0512e0a.htm

- http://www.dordt.edu/academics/programs/engineering/senior_design/2010/gasifier.shtml

- http://www.youtube.com/watch?v=JsO45IPDyXg

- http://www.youtube.com/watch?v=cmm5R_km4Kk