Municipal Solid Waste Gasification

The gasification of municipal solid waste (MSW) has grown substantially during the last decade, mainly because conventional incineration methods are not environmentally friendly, and because gasification technology is improving somewhat rapidly. This type of feed is not very easy to handle; many different types of wastes may be congealed into one huge mess, which will be fed to the gasifier. The pretreatment for this involves manual or mechanical: sorting, shredding, mixing with other materials (usually that are easier to gasify, such as coal), drying and pelletization. The purpose of the pretreatment is mainly to produce consistency in the chemical and physical characteristics of the feed.

The syngas from this process is very corrosive and the tendency for ash fusion within the gasifier can be quite substantial. Other contaminants may be in high concentration within the product gas, such as chloride and ammonia; oxygen is usually fed in small quantities to reduce the chance of sulfur oxide and nitrogen oxide compounds. Because of the low amount of oxygen fed to the process, other factors become quite favorable: the volume of the syngas produced will be a lot less, so downstream processes are less expensive to design; a lower volume of syngas increases the partial pressures of the contaminants and particulates in the syngas, which will make the adsorption/particulate capture processes downstream much more efficient.

However, there will be a significantly high amount of tar, heavy metals, halogen, and alkaline compounds in the syngas, which will make the process quite difficult to maintain. Catalytic activity will decrease substantially if tars are deposited on catalyst surfaces, and tar can cause downstream units of operation to become disrupted as well, such as clogging of filters and slagging in boilers or refractory surfaces. As a result, the cleanup process for MSW gasification is very costly. Fixed and fluidized beds can be used for MSW gasification, but high capacity beds have proven the most efficient; this is because high capacity gasifiers allow for more variable fuel feed, high turbulent flow through the bed (which helps to maintain uniform process temperatures throughout the vessel), and very good interaction between gases and solids, which will increase carbon conversion. Circulating fluidized bed gasifiers typically have a high capacity than many other gasifiers.

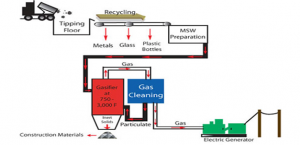

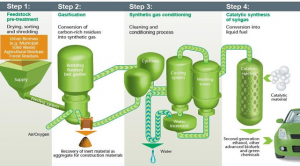

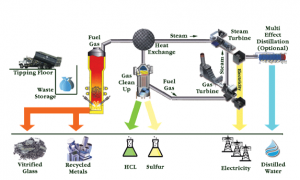

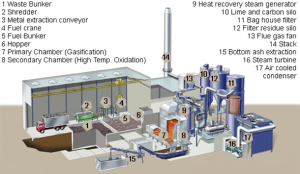

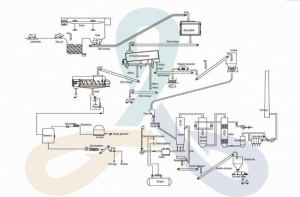

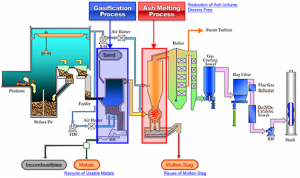

Flow Diagrams

(Source: http://www.altenergymag.com/emagazine.php?issue_number=09.06.01&article=zafar)

(Source: http://www.cnet.com/news/municipal-trash-to-ethanol-plant-opens-in-canada/)

(Source: http://www.renewablegreenenergypower.com/the-waste-to-energy-process-of-gasification/)

(Source: http://www.wtert.eu/default.asp?Menue=12&ShowDok=15)

(Source: http://shenjiasanwa.en.alibaba.com/product/545339406-213108086/Waste_To_Energy_municipal_solid_waste_gasification_system.html)

(Source: http://www.mhiec.co.jp/en/products/recycle/city/meltingsystem/index.html)

Equipment

Shredder

Fuel Crane

Fuel Bunker

Hopper

Heat Recovery Steam Generator

Bag House Filter

Air Cooled Condenser

Videos

MSW & RDF Gasification Power Plant - Zero Waste & Emissions

MSW Gasification Demo

References

- http://www.altenergymag.com/emagazine.php?issue_number=09.06.01&article=zafar

- http://news.cnet.com/8301-11128_3-20015203-54.html

- http://www.renewablegreenenergypower.com/the-waste-to-energy-process-of-gasification/

- http://www.wtert.eu/default.asp?Menue=12&ShowDok=15

- http://shenjiasanwa.en.alibaba.com/product/545339406-213108086/Waste_To_Energy_municipal_solid_waste_gasification_system.html

- http://www.mhiec.co.jp/en/products/recycle/city/meltingsystem/index.html

- http://stlenergy.org/?attachment_id=461

- http://www.chuden.co.jp/english/corporate/press2006/1108_3.html

- http://www.youtube.com/watch?v=RVDh6TRed_E

- http://www.youtube.com/watch?v=IWr7NsP0Eag