Entrained Flow Pyrolysis

Entrained flow pyrolysis is a pyrolysis system that utilizes some type of mixture or slurry as the feed to the system/process; it is favorable as a pyrolysis option particularly because of its similarities to coal gasification systems. One of the big issues with entrained flow pyrolysis is the effects of gas pressure on the heat transfer; this potential increase in pressure will affect the temperature profile within the reactor, and may not be suitable for operating conditions. This is accounted for with a much shorter residence time in the pyrolysis reactor; a smaller particle size may also be needed depending on the operating conditions. This type of process may require temperatures as high as 1400 °F, residence times as short as 0.2 seconds, and pressures as high as 5 atm; increasing pressure can inadvertently reduce tar yield/content with increase in pressure, and at increased temperatures, tar content can be substantially reduced even at lower pressures due to tar cracking.

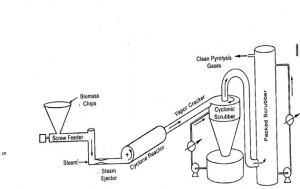

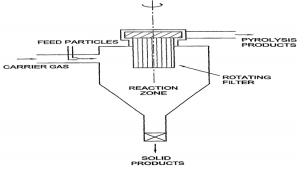

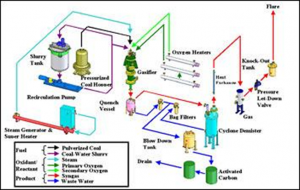

Flow Diagrams

(Source: http://bioweb.sungrant.org/Technical/Biopower/Technologies/Pyrolysis/Default.htm)

(Source: http://www.freepatentsonline.com/7202389.html)

(Source: http://www.slideserve.com/shadow/effect-of-experimental-conditions-on-biomass-gasification-in-an-entrained-flow-reactor)

Equipment

Steam Ejector

Screw Feeder

Cyclonic Scrubber

Packed Scrubber

Quench Vessel

Knockout drum

Activated Carbon Bed

Flare

Heat Exchanger

Videos

Pyrolysis R&D

http://www.nrel.gov/biomass/thermochemical_conversion.html?print

References

- http://alternativefuels2.tpub.com/3054/30540007.htm

- http://www.freepatentsonline.com/7202389.html

- http://jcwinnie.biz/wordpress/?p=2412

- http://bioweb.sungrant.org/Technical/Biopower/Technologies/Pyrolysis/Default.htm

- http://www.slideserve.com/shadow/effect-of-experimental-conditions-on-biomass-gasification-in-an-entrained-flow-reactor

- http://www.nrel.gov/biomass/thermochemical_conversion.html?print