Free Fall Pyrolysis

In pyrolysis, a free fall reactor can be used as opposed to other more conventional methods; in this process, the feed is injected to a vertical pipe. This pipe/reactor is externally heated to 500 °C. The feed is pulverized using a knife mill before the reactor and feed through a screw feeder. The feed will travel downward to the bottom of the pipe and go through actual pyrolysis all the way down. Gas cleanup and quenching equipment are needed for oil collection and gas separation.

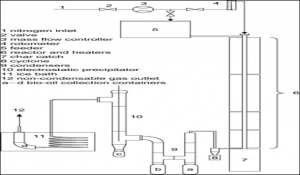

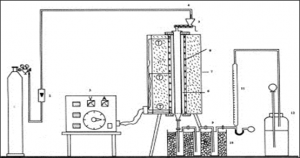

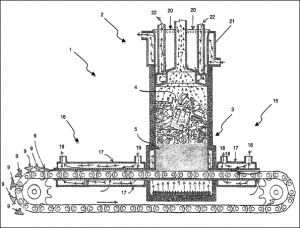

Flow Diagrams

(Source: http://www.sciencedirect.com/science/article/pii/S0960852411013757)

(Source: http://www.sciencedirect.com/science/article/pii/S0016236106000949)

(Source: http://www.google.com/patents/US8349139)

Equipment

Rotameter

Electrostatic precipitator

Knife Mill

Screw Feeder

Videos

References

- http://www.cset.iastate.edu/research/current-research/alternative-pyrolyzer-design-free-fall-reactor/

- http://www.sciencedirect.com/science/article/pii/S0960852411013757

- http://www.sciencedirect.com/science/article/pii/S0016236106000949

- http://www.google.com/patents/US8349139

- http://www.slideserve.com/mercury/country-report-usa