Fermentation of Cassava to Form Ethanol

Cassava (Manihot esculenta Crantz) is a shrubby perennial crop in the Family of Euphorbiaceae. It is also named others, depending upon geographic regions such as yucca in Central America, mandioca or manioca in Brazil, tapioca in India and Malaysia and cassada or cassava in Africa and Southeast Asia. Cassava is mostly cultivated in tropics of Africa, Latin America and Asia, located in the equatorial belt, between 30degrees north and 30degrees south. The crop produces edible starch-reserving roots which have long been employed as an important staple food for millions of mankind as well as animal feed. Due to the fact of ease of plantation and low input requirement, cassava is mostly cultivated in marginal land by poor farmers and is sometimes named as the crop of the poor. In these planting areas, cassava plays an essential role not only as food security, but also income generation. The application of cassava as renewable feedstock is now expanded to biorefinery, i.e. a facility that integrates processes and equipment to produce fuels, power, chemicals and materials from biomass (Fernando et al.,2006). With this regard, cassava is signified as a very important commercial crop that can have the value chain from low-valued farm produces to high-valued, commercialized products. When ethanol is produced by yeast fermentation of sugar feedstock such as sugar cane, molasses, sugar beet and sweet sorghum, yeast can directly consume simple sugars and convert them to ethanol. However, starch and cellulose feedstock are a polymer of glucose and cannot directly be utilized by yeast. They have to be converted or depolymerized to glucose prior to yeast fermentation. Depolymerization or hydrolysis of starch is much simpler and more cost effective than that of cellulosic materials and can be achieved by acid or enzyme or a combination of both.

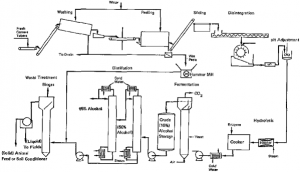

Flow Diagram

(Source: http://www.nzdl.org/gsdl/collect/envl/archives/HASH69c1.dir/p16.gif)

Equipment

Video Links

References

- http://cdn.intechopen.com/pdfs/27348/InTech-Cassava_bioethanol.pdf

- http://www.nzdl.org/gsdl/collect/envl/archives/HASH69c1.dir/p16.gif