Membrane Recycle Bioreactor Fermentation

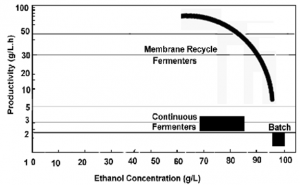

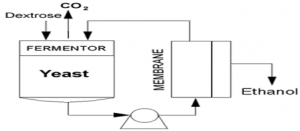

Alcoholic fermentation is a biological process that transforms sugars to ethanol; this is done in the absence of oxygen through microbial interactions, making it an anaerobic enzymatic process. Commercial production of this product will yield carbon dioxide and potentially feed for livestock. However, high costs are associated with this process: long fermentation times (20-60 hours), high capital costs for large volume vessels, and high energy costs for agitation and purification of the ethanol. Different bioreactors can directly affect these costs, as well as the general setup of the process; a continuous membrane bioreactor uses membrane technology to separate the yeasts from the ethanol as it is being produced. This technology is advantageous because: there is no need for continuous shut down and start up to remove ethanol, yeast doesn’t deactivate because of high ethanol concentrations, and recycle of the yeasts is more efficient since the cells are not washed out during ethanol collection.

Flow Diagrams

(Source: http://faculty.fshn.illinois.edu/~mcheryan/ethanol.htm)

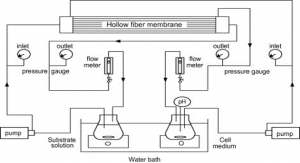

(Source: http://faculty.fshn.illinois.edu/~mcheryan/ethanol.htm)

(Source: http://ntur.lib.ntu.edu.tw/bitstream/246246/90108/1/115.pdf)

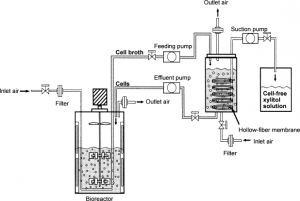

(Source: http://www.ibichematur.com/biostil-technology.htm)

Equipment

Videos

TPP TubeSpin Bioreactor Tubes from MIDSCI

References

- http://www.sciencedirect.com/science/article/pii/S0376738806003930

- http://www.sciencedirect.com/science/article/pii/S1389172306705357

- http://www.sciencedirect.com/science/article/pii/S1359431199000423

- http://www.anilbioplus.com/Manufacturing.aspx

- http://www.ibichematur.com/biostil-technology.htm

- http://www.sciencedirect.com/science/article/pii/S0376738899002550

- http://www.mypurchasingcenter.com/mro-indirect/industry-articles/center-ethanol-plant-finds-efficiencies/

- http://www.rpi.edu/dept/chem-eng/Biotech-Environ/FERMENT/vacferm.htm