Gasification of Wood

Gasification is a process that converts organic or fossil based carbonaceous materials into carbon monoxide, hydrogen and carbon dioxide. This is achieved by reacting the material at high temperatures (>700 °C), without combustion, with a controlled amount of oxygen and/or steam. The resulting gas mixture is called syngas which is itself a fuel. The power derived from gasification and combustion of the resultant gas is considered to be a source of renewable energy if the gasified compounds were obtained from biomass.

In a gasifier, the carbonaceous material undergoes several different processes: The dehydration or drying process occurs at around 100°C. The pyrolysis (or de-volatilization) process occurs at around 200-300°C. Volatiles are released and char is produced, resulting in up to 70% weight loss for coal. The combustion occurs as the volatile products and some of the char reacts with oxygen to primarily form carbon dioxide and small amounts of carbon monoxide, which provides heat for the subsequent gasification reactions. The gasification process occurs as the char reacts with carbon and steam to produce carbon monoxide and hydrogen. In addition, the reversible gas phase water gas shift reaction reaches equilibrium very fast at the temperatures in a gasifier. This balances the concentrations of carbon monoxide, steam, carbon dioxide and hydrogen.

In essence, a limited amount of oxygen or air is introduced into the reactor to allow some of the organic material to be "burned" to produce carbon monoxide and energy, which drives a second reaction that converts further organic material to hydrogen and additional carbon dioxide. Further reactions occur when the formed carbon monoxide and residual water from the organic material react to form methane and excess carbon dioxide. This third reaction occurs more abundantly in reactors that increase the residence time of the reactive gases and organic materials, as well as heat and pressure. Catalysts are used in more sophisticated reactors to improve reaction rates, thus moving the system closer to the reaction equilibrium for a fixed residence time.

The choice of feedstock determines the gasifier design. Three designs are common in wood gasification: updraft, downdraft and crossdraft. In an updraft gasifier, wood enters the gasification chamber from above, falls onto a grate and forms a fuel pile. Air enters from below the grate and flows up through the fuel pile. The syngas, also known as producer gas in biomass circles, exits the top of the chamber. In downdraftor crossdraft gasifiers, the air and syngas may enter and exit at different locations.

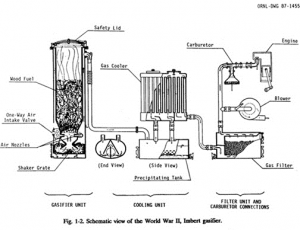

Flow Diagram

(Source: http://matadormodels.co.uk/other_pics/imbert_gas_generator.jpg)

Equipment

Video links

Econoburn Wood Gasification Boiler

Downdraft Wood Gasification Barrel Stove